What does metal fabrication mean?

Most of us don’t know what sheet metal fabrication is, but it is a part of our everyday lives. You may be using it right this very minute while reading this article. Sheet metal fabrication covers several different processes where sheet metal is used. There are several different professionals in various industries where sheet metal fabrication is part of the process.

Two industrial terms that are linked and often confused as being the same thing is ‘fabrication’ and ‘manufacturing’ because both are a process of construction or production. Yet, they are totally different, and with that, we are going to discuss sheet metal fabrication in this article.

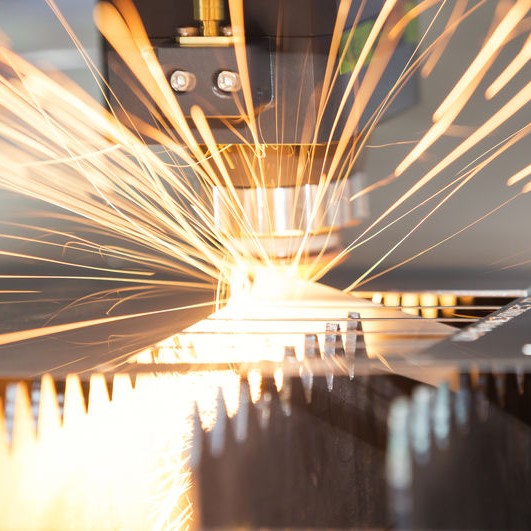

Sheet metal fabrication is the process of using one or more different processes to combine other standardized parts to construct other products. Sheet metal fabrication, for example, is achieved by cutting, bending, and assembling sheet metal resulting in metal structures.

What is an example of fabrication?

Those that know how to do metal fabrication and create sheet metal fabrication products are professional fabricators. Some of those products include:

- Metal Furniture

- Stainless steel storage units

- Metal cabinets

- Steel shelving

- Stairwell Railings

- Fencing

- Cages

- HVAC Industry

- Ductwork

- Grating

- Venting

- Lighting Hoods

- Scissors

- Structural Elements

- Stainless steel bridge skeletons

- Aircraft framework

- Silverware

What are the types of fabrication?

Sheet metal fabrication is done by taking raw sheet metal stock material and turning it into a part or piece that is used in the assembly process of another product. Sheet metal fabrication and welding are often used together in addition to several other steps in the process of other common steps involved, some of those being the following:

- Cutting the sheet metal

- Folding the sheet metal

- Machining to shape the sheet metal

- Punching holes in the sheet metal

- Shearing the sheet metal

- Stamping imprints on the sheet metal

- Additive Manufacturing to add sheet metal material in creating another object

What type of steel is used for sheet metal?

Different metals and metal alloys can be produced in sheets and used for sheet metal fabrication parts. The application requirements are considered when choosing which type of metal or metal alloy along with these factors:

- It Has Configurability

- It Is Weldable

- It Resists Corrosion

- The Durability and Strength

- The Weight

- The Cost

Popular choices of metal and metal alloys for sheet metal fabrication include:

- Stainless Steel: Available in a non-magnetic form and doesn’t require heat or any type of stress relief for manufacturing. Comes in different grades of corrosion resistance, configurability, and weldability.

- Cold rolled steel: Industry referred to as CRS provides smooth finished steel with a tighter tolerance for forming. Available in two different alloys of 1008 and 1018.

- Pre-plated steel: A sheet metal material that comes as hot-dip galvanized steel or as galvannealed steel.

- Aluminum: This is a moderately-priced material with a wide range of characteristics in different grades that can meet different application requirements. From a relatively low strength that is chemical resistant and weather-resistant but ductile and weldable for deep drawing. Also available in an affordable, formable, stronger, weldable grade that is corrosion-resistant or a significantly stronger grade that is still formable, corrosion-resistant, and weldable. Another grade option is a structural alloy that isn’t formable but is a strong, corrosion-resistant material that can be welded with a strong weld.

- Brass/Copper: When a ‘red’ color metal is required by designers and engineers, the ETP of brass or copper are the best choices in metal for sheet metal fabrication project.

What is the strongest sheet metal?

There is more than one metal to be considered “the strongest sheet metal”. Among those are:

- Carbon Steel

- Chromium

- Iconel – a heat-resistant alloy combination of nickel, chromium, and iron.

- Stainless Steel

- Titanium

- Tool Steel – a variety of alloy steel and carbon steel

- Tungsten

In Closing – Just where do metal fabrication ideas come from?

When developing a product, first comes the conception or idea. This could be any person from a personal experience or in conjunction with a process or product they have already that could be improved upon.

A product design doesn’t go directly to manufacturing. After the conception or idea, the product design state follows, with engineering and protoype next. Then the sheet metal fabrication stage comes. Before a product idea can become a product, these other steps are necessary, especially if customization is necessary.

Throughout the process, once a concept or an idea gets to the design stage and going forward, it is teamwork toward getting that end result that the originator had envisioned. Rarely does a concept or idea of a product go right from design to production. There is collaboration with engineering, the originator, and the rest of the team.

Once the product is ready to sell, there are the other tasks of finding vendors and a marketing plan. The marketing plan involves several layers as well, all of which can take some time before selling the product comes to fruition.